Apprenticeship, reputation, recommendation,

skill and status; The Transaction Project takes these aspects of

craft as the basis for a network of production. Building on two

years of investigation, the project brings together the work of

ceramicist

Jonathan

Keep, artist researcher

Charles Stern and design

studio

Unfold. Working with a

technique that applies 3D printing to the problem of ceramic and

glass compatibility, the group has created an iterative process

that allows for rapid testing of materials and form. The results

are composite objects that possess integrity toward handmade and

digital skills.

Apprenticeship,

reputation, recommendation, skill and status; The Transaction

Project takes these aspects of craft as the basis for a network of

production. Building on two years of investigation, the project

brings together the work of ceramicist

Jonathan Keep, artist

researcher

Charles

Stern and design studio

Unfold. Working with a technique that

applies 3D printing to the problem of ceramic and glass

compatibility, the group has created an iterative process that

allows for rapid testing of materials and form. The results are

composite objects that possess integrity toward handmade and

digital skills.

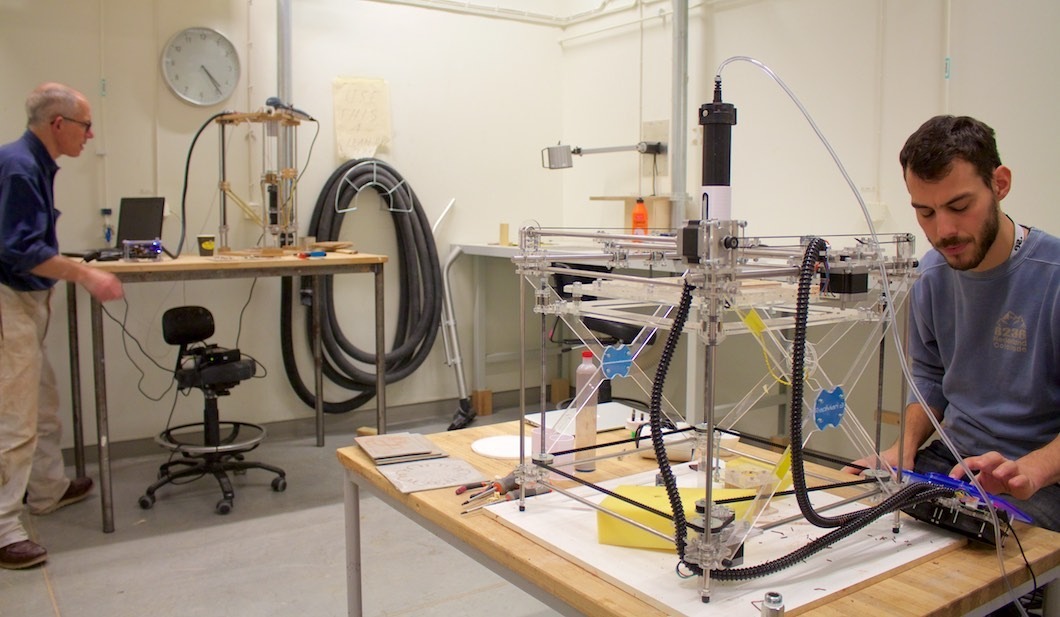

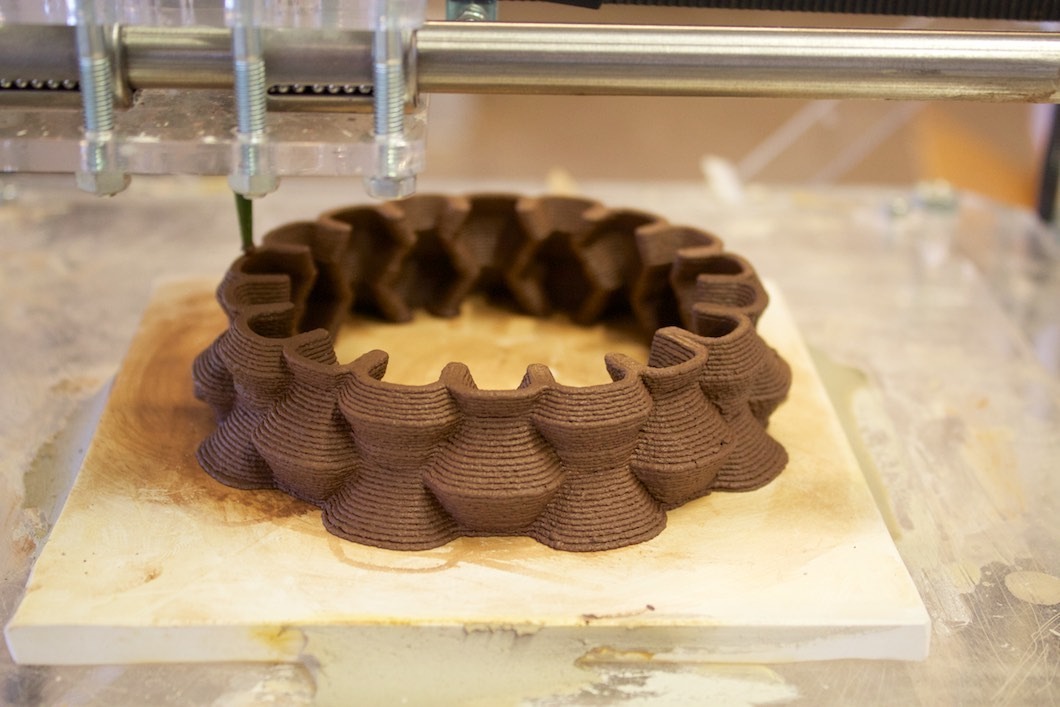

At the core of the project is a technical innovation: the

combination of 3D printed ceramic moulds with blown glass. Through

a long period of material testing in collaboration with many

different actors, a process has emerged which addresses the

compatibility issues between clay and glass. Few works successfully

combine these materials in a hot state because clay and glass

possess different rates of contraction and expansion. Charles Stern

has initiated an investigation into this problem and with the help

of experts including Jonathan keep and Unfold, has identified a

working method that uses ceramic 3d printers and traditional

glassblowing. This is significant for artistic practice and

material science because it opens up a new language of form and

offers an inexpensive, non patented method to explore these two

‘incompatible’ materials.

The Transaction project makes use of 3D printing’s capacity

to iterate swiftly; designs that are 3D printed in clay can be

changed and produced to suit the conditions at hand; traditional

methods of hand building or slip casting being more time consuming

and expensive. Secondly, it embraces the digital

‘reshuffle’ where the use of novel technologies brings

new people, new skills and new perspectives to old problems and

orthodoxies. Thirdly, the design process can be distributed; the

use of cad files and transportable machinery means that ownership

of the process can be devolved to allow more people to become

stakeholders. This entails a wide conception of the designers role

where the chief responsibility is to create a network or system

which enables other makers.

The traditional conception of a craft community has a number of

characteristics: person to person teaching in the form of an

apprenticeship, a strong emphasis on reputation linking status with

the acquisition of skill, and a system of employment that is based

on personal recommendations.

The Transaction Project will continue to take these features as the

basis to develop a network of production that uses a chain of

recommendation to develop and disseminate a new method of digital

fabrication. It takes a technical innovation: a process for ceramic

and glass production and distributes it amongst the owners of

independent glass studios. In this way the project will articulate

a role for digital fabrication as a connecting force for small

scale, bespoke manufacturing. The aim is to create a resource that

supports studio owners in a challenging market.

The project builds on previous studies from 2013-2015 including

residency and work periods at:

Konstfack University College of Arts,

Crafts and Design in Stockholm, Sweden;

Corning Museum of Glass in Corning,

USA; Design Studio

Unfold &

GlazenHuis in Belgium

and

The Glass

Factory in Småland, Sweden

Produced with the generous support of:

Konstfack University College of Arts,

Crafts and Design;

Corning

Museum of Glass;

The Glass

Factory and

Emmaboda Kommun,

Småland, Sweden;

The Swedish

arts grants committee and

The Flemish authorities

Pieces from the Transaction Project have been acquired by the

following institutes for their permanent collection: CID Grand

Hornu (BE) & The Glass Factory Boda (SE)

The Transaction Project has been exhibited in, amongst others:

Cheongju International Craft Biennale (KR); The Glass Factory Boda

(SE); Design Museum Ghent (BE),

INTERSECTIONS #4 at Art

& Design Atomium Museum, Brussels (BE) and

Making a

Difference/A Difference in Making at Red Dot Design Museum

(DE)

fig. 01, 05: photography by Viktor Sjödin

fig. 03, 11, 12, 15: photography by Hans Runesson

other photography by Unfold

contact

contact