From knife to hammer to 3d printer, the

influence of tools on a design is not to be underestimated. Yet for

a long time the instruments of production were closed systems. This

is now changing. Following the personal computer and a range of

digital advances, the advent of the personal fabricator has

provoked a revival of the idea of “making your own

things.” There is a new species of design, semi-industrial

craft, and although the definition of craft often refers to work by

hand, in this context it reflects a renewed interest in building

knowledge through repetition and practice of a skilled trade using

the aid of tools.

From knife to hammer

to 3d printer, the influence of tools on a design is not to be

underestimated. Yet for a long time the instruments of production

were closed systems. This is now changing. Following the personal

computer and a range of digital advances, the advent of the

personal fabricator has provoked a revival of the idea of

“making your own things.” There is a new species of

design, semi-industrial craft, and although the definition of craft

often refers to work by hand, in this context it reflects a renewed

interest in building knowledge through repetition and practice of a

skilled trade using the aid of tools.

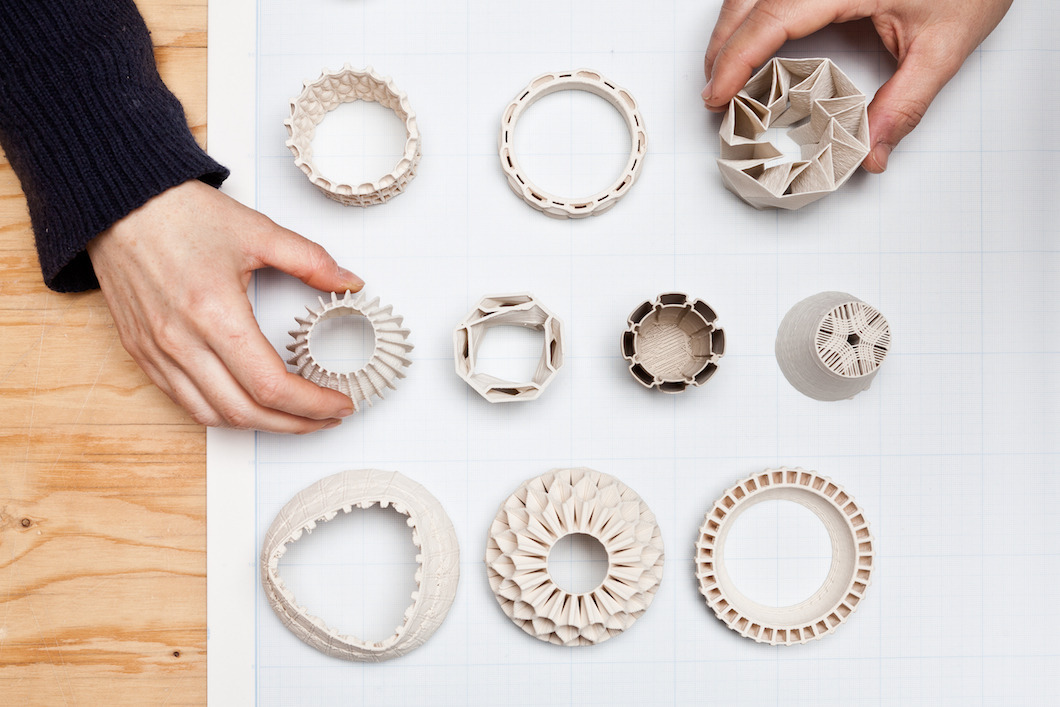

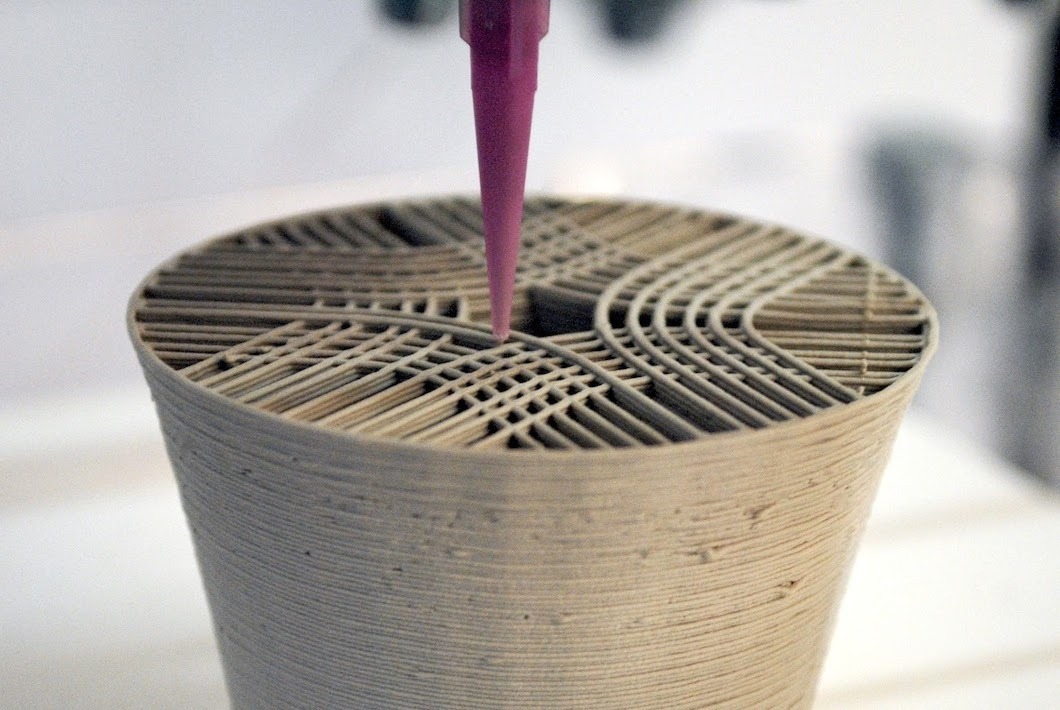

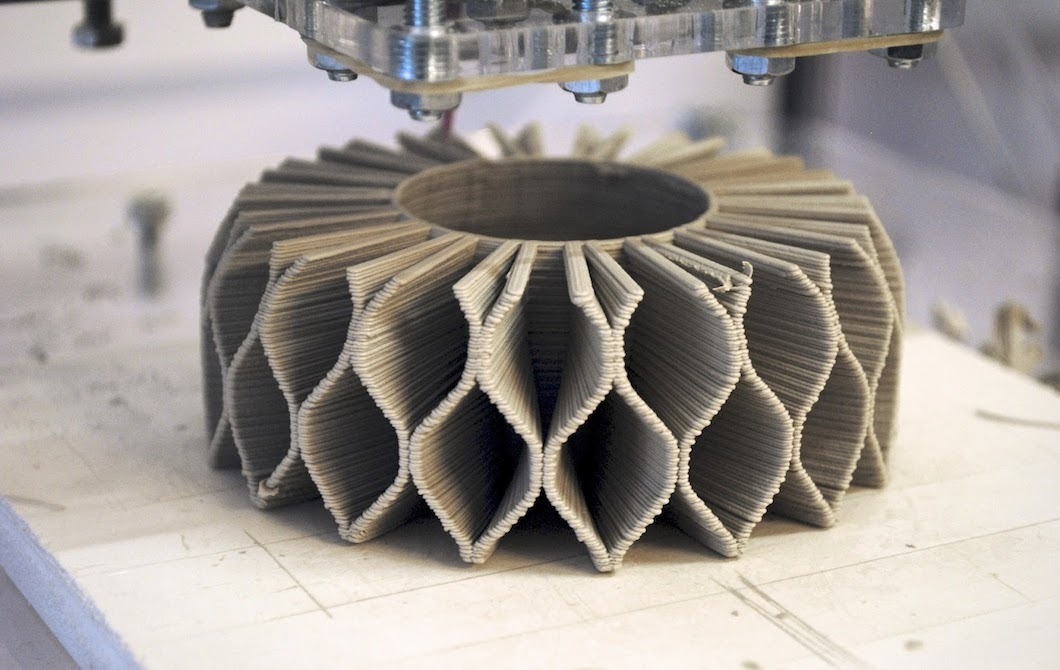

Unfold’s 3d printing process for ceramics not only harnesses

the potential of new technology and materials but also projects the

past history of specific techniques into the future. The printer

has a great resonance with the way traditional potters handled

clay, however because of its ability to produce such fine layers,

new forms are possible.

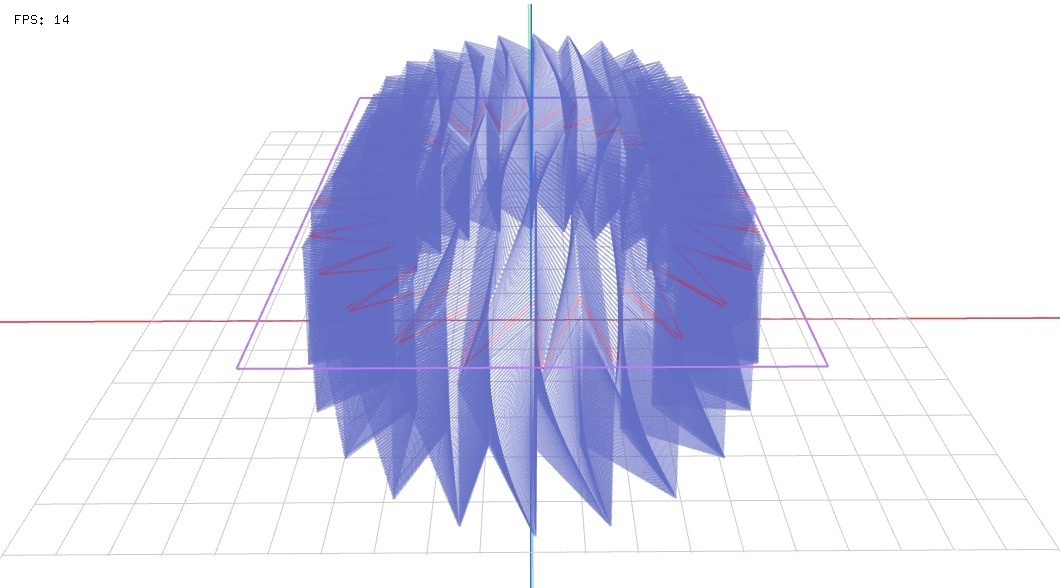

Together with

Tim Knapen Unfold

developed custom software that allows detailed line level control,

unlocking a new form language in 3d printing.

The ceramic 3d printer has been integrated as part of Unfold's

installations

L’Artisan

Électronique -where it made its first appearance- and

Stratigraphic

Manufactury and has been used for producing ceramics for

The Peddler,

Open Source

Waterfilters and

Stratigraphic Porcelain.

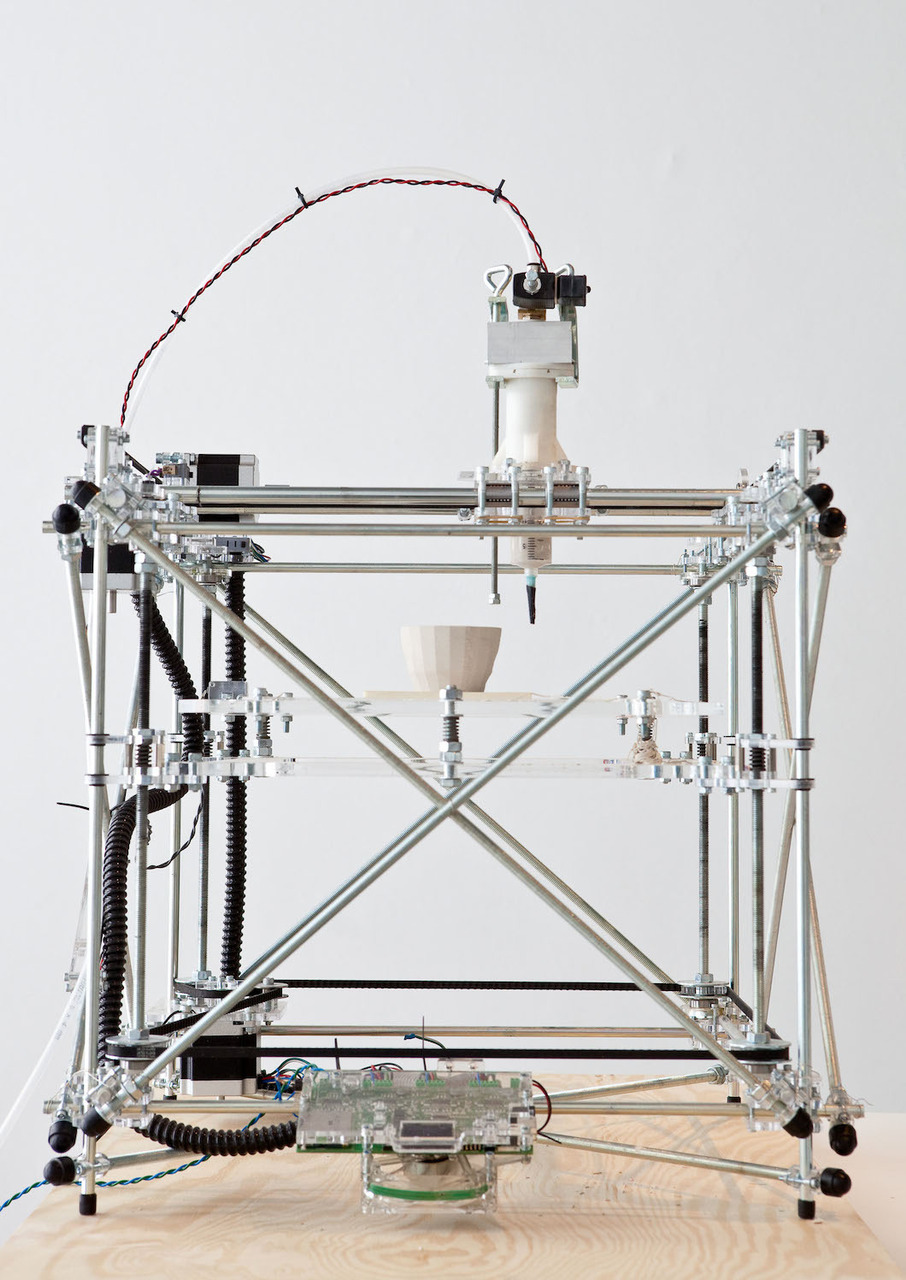

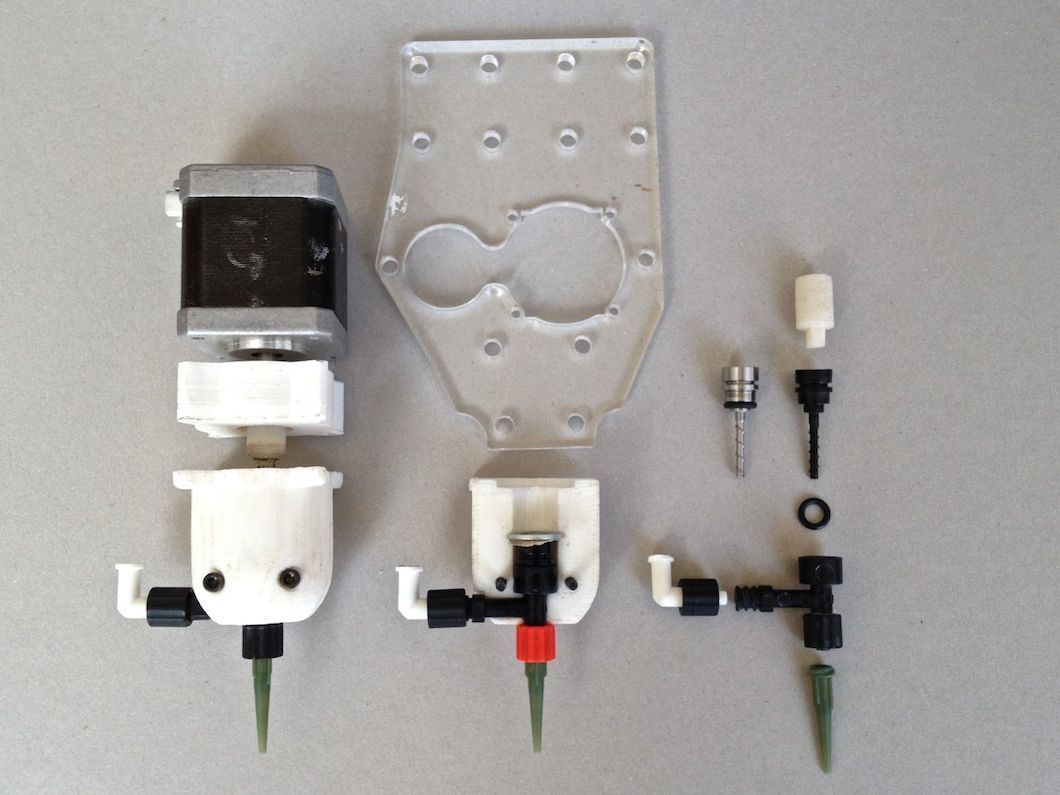

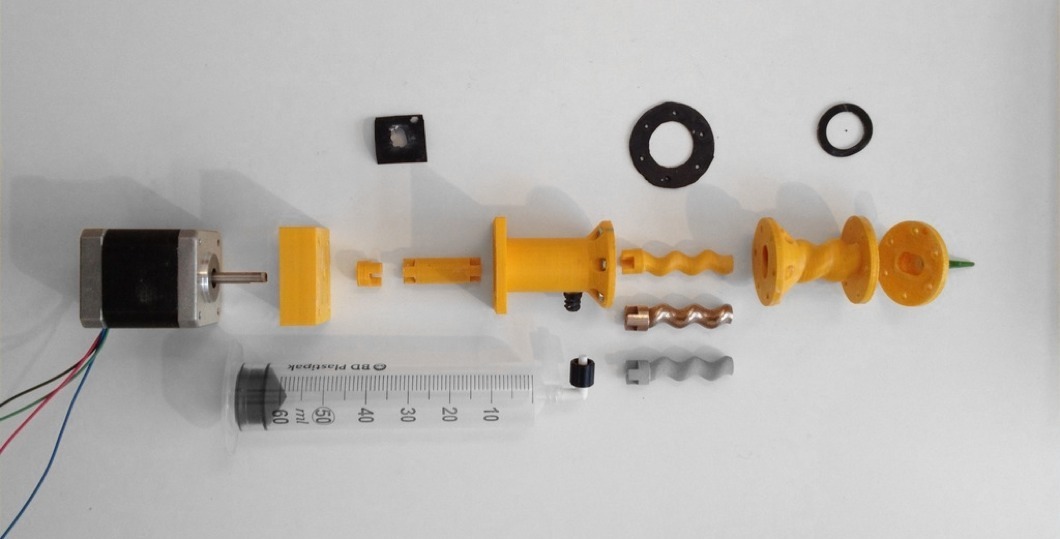

The ceramic 3d printing process pioneered by Unfold in 2009 is

based on the open source

RepRap

project, the various ceramic extruders currently developed would

not have been possible without the work done in the RepRap

community. All our development on the ceramic 3d printing process

is documented under a Creative Commons license at the

Unfold Fab blog.

Over the past years Unfold has been actively diffusing this new

method for producing ceramics by assisting artists, designers,

universities and institutes worldwide to setup their own ceramic 3d

printers based on our open system. This includes (amongst others):

Jonathan

Keep -who himself assisted many more- (UK),

Cranbrook Academy

of Art, Detroit (US),

EKWC/European Ceramic Workcentre

(NL),

Hyperwerk Institute for

Postindustrial Design (CH),

Academy

of Fine Arts Saarbruecken (DE),

Colorado State University(US),

Alfred University (US),

Eran Gal Or / Studio Under (IL), FabLab Zuid-Limburg (NL),

University of West

England/Centre for Fine Print Research, Bristol (UK),

VHL, University of Applied

Sciences (NL) and all artists involved in the

Stratigraphic Manufactury

project.

Together with

Jonathan

Keep, Unfold initiated

Make Your Own Ceramic 3D Printer,

an online community dedicated to sharing and developing ideas

around ceramic 3d printing. With the demise of Google+ in 2019 the

community migrated to Wikifactory adding

Tom Lauerman as a third admin.

Many thanks to the team at

WikiFactory for making this

transition happen.

You can find the community at

wikifactory.com/+Ceramic3DPrinting

fig. 01-05: photography by Kristof Vrancken

fig. 06-13: photography by Unfold

contact

contact